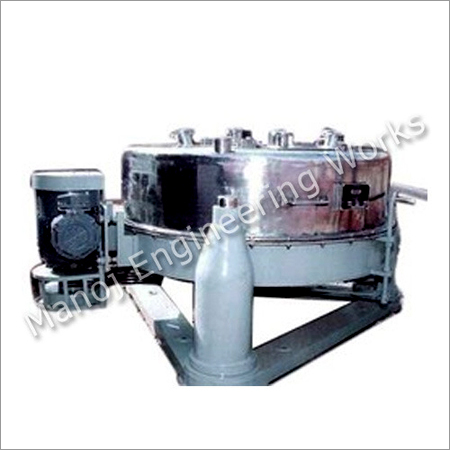

Textile Hydro Basket

Price 150000 INR/ Piece

Textile Hydro Basket Specification

- Type

- Hydro Basket

- Material

- Stainless Steel

- Capacity

- 30-50 Kg/Batch

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Voltage

- 220 V

- Frequency (MHz)

- 50 Hz

- Size

- Standard

- Width

- Customized

- Weight

- Approx. 60-90 Kg

- Dimension (L*W*H)

- 700 x 700 x 950 mm

Textile Hydro Basket Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Payment Terms

- Cash in Advance (CID)

- Main Domestic Market

- All India

About Textile Hydro Basket

Textile Hydro Basket

Manoj Engineering is name to reckon with, engaged as manufacturer and exporter of a versatile range of Textile Hydro Centrifuge Basket. Constructed out of looped wedge wires in conical shape, cylindrical shape and in double Cylindrical shape i.e. pusher type centrifuge, the wedge wire baskets have clear advantage of very high filtration efficiency, longer life and accurate aperture over any other conventional screen baskets. Further, these conical and cylindrical baskets can be customized to suit the customer requirement and maximum efficiency to meet industry standards.

Features

- Apt for textile industry

- Performance and functionality intact

- Resistance to corrosion

| Design Type | Standard |

| Drum Capacity | 150 L |

| Condition | New |

We are a leading manufacturer and supplier of Basket Centrifuge to our valuable clients.

Efficient Water Extraction for Textiles

The Textile Hydro Basket is engineered to streamline the water removal process from fabrics. Its high-speed basket and optimized design help in significantly reducing drying times, improving workflow in textile mills and processing plants. The semi-automatic operation enables reliable performance without the need for complex computerized controls.

Robust Stainless Steel Construction

Built from corrosion-resistant polished stainless steel, the hydro basket is designed for longevity and low maintenance. The cylindrical perforated basket promotes uniform water drainage, while the safety-enabled lid and durable mounting offer both operator protection and stability during operation.

User-Centric Features and Customization

From its low noise output to customizable width and batch capacity, this hydro basket is tailored to diverse textile applications. The 220 V, 50 Hz power source ensures compatibility with standard industrial settings, and floor mounting simplifies installation in various facility layouts.

FAQs of Textile Hydro Basket:

Q: How is the Textile Hydro Basket installed and operated in a textile processing unit?

A: The hydro basket is floor-mounted and connects to a standard 220 V, 50 Hz power supply. Operators load textiles into the cylindrical perforated basket, secure the safety lid, and start the semi-automatic cycle for effective water extraction at 1000 RPM.Q: What benefits does the stainless steel construction provide?

A: Stainless steel offers high corrosion resistance and durability, ensuring the basket remains reliable even with continuous exposure to water and chemicals common in textile processing environments.Q: When should this hydro basket be used during textile production?

A: The basket is typically used after washing or dyeing procedures to remove excess water from fabrics before further finishing or drying steps, improving efficiency and reducing processing times.Q: Where can this hydro basket be implemented in the textile supply chain?

A: It is suited for textile mills, garment manufacturing plants, and laundering facilities across India, especially within export, manufacturing, and supplier operations that handle batch loads up to 50 kg.Q: What is the process for draining water during operation?

A: Upon completion of the spinning cycle, the provided drain valve facilitates swift removal of extracted water, helping maintain a clean working environment and faster turnaround between batches.Q: How does the safety-enabled lid locking feature enhance operational safety?

A: The safety lid locking mechanism prevents accidental opening during high-speed operation, ensuring operator safety and reducing the risk of spills or injuries.Q: Does the Textile Hydro Basket require computerized controls for use?

A: No, the unit is semi-automatic and does not depend on computerized systems, making it user-friendly and straightforward to operate with essential controls for efficient batching.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centrifuge Hydro Extractor Category

4 Point Suspension Centrifuge

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : 4 Point Suspension Centrifuge

Size : Standard

Dimension (L*W*H) : 1500 x 1200 x 900 mm

Capacity : 100 to 500 kg/hr

SS Centrifuge

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Centrifuge Machine

Size : Standard and Custom sizes available

Dimension (L*W*H) : 800 x 600 x 1000 mm (varies with capacity)

Capacity : 30 to 500 Litres (as per model)

Industrial Centrifuge Machine

Price 150000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Type : Industrial Centrifuge Machine

Size : Standard

Dimension (L*W*H) : 1800 x 1200 x 1500 mm

Capacity : 5001000 Liters per hour

Beg Lifting 4 Point Suspension Centrifuge

Price 325000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : 4 Point Suspension Centrifuge

Size : Standard

Dimension (L*W*H) : Customizable

Capacity : 100500 Ltr

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry