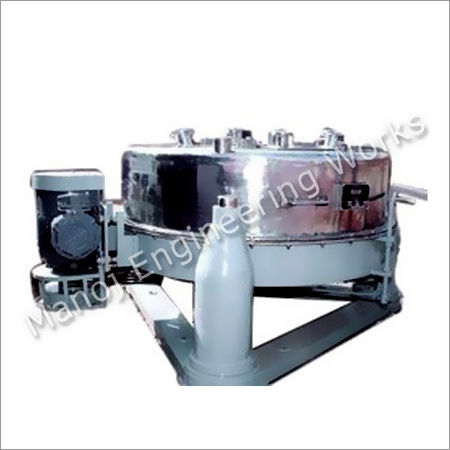

SS Centrifuge

Price 150000 INR/ Unit

SS Centrifuge Specification

- Type

- Centrifuge Machine

- Material

- Stainless Steel (SS)

- Capacity

- 30 to 500 Litres (as per model)

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Voltage

- 220-415 V

- Frequency (MHz)

- 50 Hz

- Belt Diameter

- 350-600 mm (as per design)

- Size

- Standard and Custom sizes available

- Width

- Varies with Model

- Weight

- 150-650 kg (approx.)

- Dimension (L*W*H)

- 800 x 600 x 1000 mm (varies with capacity)

- Control Panel

- Optional Digital/Analog Timer and Control Panel

- Surface Finish

- Mirror / Matt Polish

- Installation

- Floor Mounted with Anti-Vibration Mountings

- Noise Level

- <70 dB

- Drive System

- Direct/ Belt Driven

- Discharge Type

- Manual Top Discharge / Bottom Discharge

- Application

- Chemical, Pharmaceutical, Food, Textile, Wastewater Treatment

- Design

- GMP & Standard Model Options

- Gasket

- Neoprene / Silicon Rubber

- Drum Material

- SS 304 / SS 316

- Power Consumption

- As per model and motor size

- Basket Speed

- 1200 to 1550 RPM

- Safety Feature

- Mechanical and Electrical Interlocks, Braking System

- Cleaning

- Easy-to-Clean, Removable Basket

- Motor Power

- 1 HP to 7.5 HP (as per capacity)

About SS Centrifuge

We are one of the well-known manufacturer and exporter of SS Centrifuge that is used for the separation of the particles from their solution in accordance to their specifications in terms of size, shape, density, viscosity of the medium and the speed of the rotor. The size & power of the centrifuge entirely depends on the substance and ensures superior performance even in tough working conditions.

Specifications

- The capacity of centrifuge is in range from 300.mm to 2000.mm in MS/ MSRL/MSFRP/SS.

Precision Engineering and Custom Configurations

Engineered with versatility in mind, the SS Centrifuge offers a wide selection of drum materials, capacities, discharge types, and finishes to meet varied industry demands. With both standard and GMP-compliant designs available, each machine can be tailored to specific operational requirements. Its stainless steel construction ensures long-lasting durability and resistance to corrosion, ideal for rigorous industrial applications.

User-Friendly Operations and Safety Features

Safety and ease of use are at the core of this centrifuges design. Anti-vibration mountings, mechanical and electrical interlocks, and an effective braking system provide safe and stable operation. The semi-automatic process with manual discharge options, combined with a removable basket, enables straightforward operation and quick maintenance, reducing downtime and maximizing productivity.

Versatile Application and Efficient Performance

The SS Centrifuge excels in a spectrum of industriesincluding chemical processing, pharmaceuticals, textiles, food production, and wastewater treatment. Its speed and discharge options, coupled with energy-efficient motor choices that match specific capacities, support a wide variety of separation processes. Optional control panels, low noise levels, and easy cleaning features further enhance its practical utility and operator comfort.

FAQs of SS Centrifuge:

Q: How does the SS Centrifuges discharge system work and what options are available?

A: The SS Centrifuge offers manual top or bottom discharge systems. Top discharge allows for material removal from the upper opening, while bottom discharge uses a dedicated lower outlet. Both methods facilitate efficient solid-liquid separation and are selected based on material type and operational preference.Q: What safety features are included in the SS Centrifuge?

A: This machine is equipped with both mechanical and electrical interlocks, a reliable braking system, and floor-mounted anti-vibration supports. These features collectively help prevent accidental operation, minimize movement, and ensure safe stopping during maintenance or unforeseen interruptions.Q: When and where is the SS Centrifuge most suitably used?

A: The SS Centrifuge is ideal for chemical, pharmaceutical, food, textile, and wastewater treatment applications. It is best utilized in environments requiring efficient solid-liquid separation and reliable, hygienic processing under controlled conditions.Q: What is the process for cleaning the centrifuge, and how is this facilitated?

A: Cleaning is straightforward due to the removable basket design. After each use, operators can detach the basket for thorough washing. The smooth, stainless steel surfaces and available mirror or matt finish ensure residues can be quickly and completely removed, upholding GMP standards.Q: How does selecting different drum materials or gaskets benefit various applications?

A: Choosing between SS 304 and SS 316 drums, as well as neoprene or silicone rubber gaskets, enables the centrifuge to withstand harsh chemicals and high temperatures. This adaptability enhances chemical resistance, extends equipment lifespan, and optimizes compatibility with the process media.Q: What options exist for controlling the centrifuge during operation?

A: Operators can select from optional digital or analog timer-equipped control panels. These allow for precise control over operation time and process parameters, accommodating both standardized and customizable workflow requirements.Q: How does the centrifuges design help reduce noise and vibration during operation?

A: With its anti-vibration mountings and balanced mechanical construction, the SS Centrifuge maintains a noise level below 70 dB, ensuring a quieter and more stable working environment. This not only promotes safety but also enhances overall comfort for operators.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centrifuge Hydro Extractor Category

Beg Lifting 4 Point Suspension Centrifuge

Price 325000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : 4 Point Suspension Centrifuge

Size : Standard

Capacity : 100500 Ltr

Material : Stainless Steel

Textile Hydro Basket

Price 150000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Type : Hydro Basket

Size : Standard

Capacity : 3050 Kg/Batch

Material : Stainless Steel

Centrifugal Hydro Extractor

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Centrifugal Hydro Extractor

Size : Standard Industrial

Capacity : 60100 kg per batch

Material : Stainless Steel

Industrial Centrifuge Machine

Price 150000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Type : Industrial Centrifuge Machine

Size : Standard

Capacity : 5001000 Liters per hour

Material : Stainless Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry