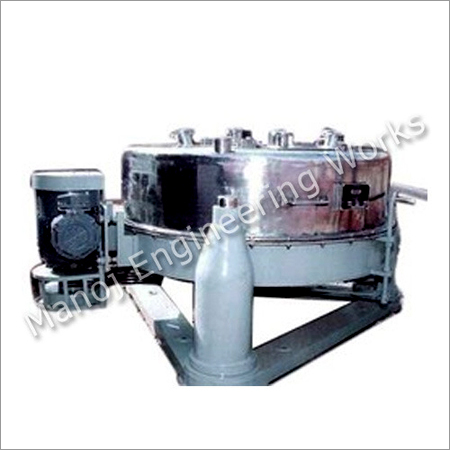

Beg Lifting 4 Point Suspension Centrifuge

Price 325000 INR/ Unit

Beg Lifting 4 Point Suspension Centrifuge Specification

- Type

- 4 Point Suspension Centrifuge

- Material

- Stainless Steel

- Capacity

- 100-500 Ltr Ltr/hr

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Voltage

- 220-440 V Volt (v)

- Frequency (MHz)

- 50 Hz Hertz (HZ)

- Preheating Plate Size

- 6

- Cutting Thickness

- 6 mm Thicknees Millimeter (mm)

- Belt Diameter

- As Per Requirement Millimeter (mm)

- Size

- Standard

- Weight

- 250-500 kg Kilograms (kg)

- Dimension (L*W*H)

- Customizable Millimeter (mm)

- Basket Speed

- 1200 RPM

- Surface Finish

- Polished

- Noise Level

- Low

- Power Source

- Electric

- Application

- Industrial Solid-Liquid Separation

- Mounting

- Floor Mounted

- Discharge Type

- Manual/Bottom Discharge

- Control Panel

- Available as Optional

- Drive Type

- Direct/ Belt Driven

- Basket Material

- SS 304/316 As Per Requirement

Beg Lifting 4 Point Suspension Centrifuge Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Others

- Supply Ability

- 1 Unit Per Month

- Delivery Time

- 45 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India, Gujarat

About Beg Lifting 4 Point Suspension Centrifuge

Product Specification

| Brand | Manoj Engineering Co. |

| Color | Standard |

| Material | Carbon Steel |

| Test Volume | 220/360 V |

| Frequency | 50/60 Hz |

| Motor Power | 5.5 kW-30 kW |

Product Description

We are engaged in manufacturing and supplying ofFour Point Suspension Centrifugeto our valuable clients.

Efficient Solid-Liquid Separation

This centrifuge offers high-speed separation for a wide range of industrial applications, utilizing its robust basket and powerful motor for reliable operation. Its suspension design minimizes vibrations, ensuring smooth performance and optimal results during continuous use. Multiple discharge and drive types provide flexibility for various process requirements.

Superior Build and Customization

Manufactured from SS304 or SS316 stainless steel, the centrifuge is resistant to corrosion and built for longevity. With customizable dimensions and capacities, this equipment can be tailored to meet specific site and processing needs, guaranteeing efficiency and safety in operation.

User-Friendly and Low Maintenance

The equipment supports semi-automatic controls, with an optional panel for more precise management. Its polished surface and quality components reduce cleaning and maintenance needs, while low noise levels create a more comfortable working environment for operators.

FAQs of Beg Lifting 4 Point Suspension Centrifuge:

Q: How does the 4 Point Suspension mechanism enhance centrifuge performance?

A: The 4 Point Suspension minimizes vibrations and stabilizes the centrifuge, resulting in smoother operation. It protects internal components and extends equipment lifespan, contributing to consistent separation efficiency during industrial processes.Q: What types of materials can be processed with this centrifuge?

A: This centrifuge is ideal for industrial solid-liquid separation and is compatible with a variety of substances, including chemicals, pharmaceuticals, and food products, thanks to its durable stainless steel basket and customizable capacity.Q: When is manual or bottom discharge recommended for operation?

A: Manual discharge is suited for batch processes with varied solid content, while bottom discharge is preferable for continuous operations requiring faster and direct removal of separated solids, helping optimize workflow.Q: Where can the Beg Lifting Centrifuge be installed?

A: Designed as a floor-mounted unit with customizable size and weight, the centrifuge can be installed in industrial facilities such as manufacturing plants, chemical processing units, or any site with standard and specialized requirements.Q: What is the process of operating this centrifuge?

A: Operation involves loading the mixture into the basket, setting parameters via the control panel (optional), and activating the centrifuge. Solids are separated as the basket spins at 1200 RPM, and discharged according to the selected methodeither manual or bottom.Q: How does the use of SS304/316 baskets benefit the user?

A: SS304 and SS316 baskets provide superior corrosion resistance and durability, ensuring safe processing of aggressive or sensitive materials. This extends the equipments usable life and guarantees product integrity.Q: What are the advantages of choosing a semi-automatic grade centrifuge with optional controls?

A: A semi-automatic grade offers a balance of cost efficiency and operational convenience. The optional control panel enables precise operation and monitoring, reducing downtime and operator workload while improving separation outcomes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centrifuge Hydro Extractor Category

4 Point Suspension Centrifuge

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : 4 Point Suspension Centrifuge

Size : Standard

Material : Stainless Steel

Voltage : 380 V

Textile Hydro Basket

Price 150000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Type : Hydro Basket

Size : Standard

Material : Stainless Steel

Voltage : 220 V

SS Centrifuge

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Centrifuge Machine

Size : Standard and Custom sizes available

Material : Stainless Steel (SS)

Voltage : 220415 V

Industrial Centrifuge Machine

Price 150000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Type : Industrial Centrifuge Machine

Size : Standard

Material : Stainless Steel

Voltage : 380 V Volt (v)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry