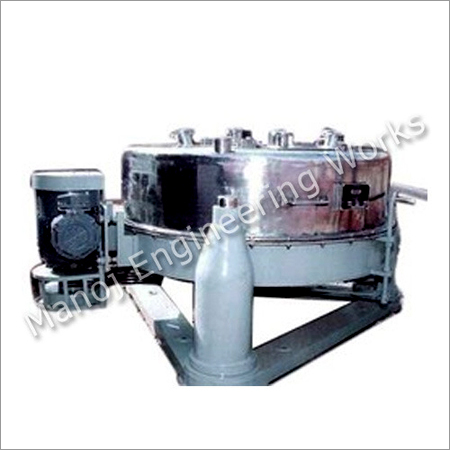

4 Point Suspension Centrifuge

Price 350000 INR/ Unit

4 Point Suspension Centrifuge Specification

- Type

- 4 Point Suspension Centrifuge

- Material

- Stainless Steel

- Capacity

- 100 to 500 kg/hr

- Computerized

- No

- Automatic Grade

- Semi Automatic

- Voltage

- 380 V

- Frequency (MHz)

- 50 Hz

- Size

- Standard

- Width

- Standard

- Weight

- 450 kg (Approx)

- Dimension (L*W*H)

- 1500 x 1200 x 900 mm

- Basket Material

- SS 304 or SS 316

- Mounting

- Four Point Suspension

- Drive Type

- Direct / Belt

- Basket Diameter

- 600 mm to 1200 mm

- Max Speed

- 2500 rpm

- Basket Height

- 300 mm to 500 mm

- Noise Level

- Low

- Application

- Chemical, Pharmaceutical, Food Processing

- Discharge Type

- Top / Bottom Discharge

4 Point Suspension Centrifuge Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- vadodara

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About 4 Point Suspension Centrifuge

4 Point Suspension Centrifuge is a simple to operate machine that can be easily mounted on upper floor and can be easily relocated. It doesnt require firm grouting. When operational, the level of vibrations is much lower. The drive of the machine has a motor which is mounted on inertia plate and is driven through V Belt which is completely closed. The body of the 4 Point Suspension Centrifuge can be opened that facilitates easy cleaning. It allows access to the internals and inside surface of outer body. The engineers can inspect internally and externally.

Product Specification

| Brand | Manoj Engineering Co. |

| Color | Standard |

| Material | Carbon Steel |

| Test Volume | 220/360 V |

| Frequency | 50/60 Hz |

| Motor Power | 5.5 kW-30 kW |

Product Description

We are engaged in manufacturing and supplying ofFour Point Suspension Centrifugeto our valuable clients.

Engineered for Reliability and Performance

Our 4 Point Suspension Centrifuge delivers dependable performance for industrial separation processes. With a stainless steel basket available in SS 304 or SS 316, and a robust suspension design, it efficiently handles a capacity of up to 500 kg/hr. Each unit is designed to minimize noise and vibration, ensuring a safer and quieter working environment. The machine meets the high standards demanded by chemical, pharmaceutical, and food processing industries.

Versatile Design with Flexible Discharge Options

Choose between top or bottom discharge configurations to best suit your operations workflow. The centrifuge supports both direct and belt drive systems, allowing for adaptability in diverse processing lines. Its semi-automatic controls simplify operation without the need for advanced computerization, making it accessible for various industrial environments while maintaining high throughput and process reliability.

FAQs of 4 Point Suspension Centrifuge:

Q: How does the four-point suspension system benefit the centrifuges operation?

A: The four-point suspension mounting significantly reduces vibration and ensures stability during high-speed operation. This not only prolongs the equipments lifespan but also enhances safety and reduces noise levels in the working environment.Q: What materials are used for the basket, and why are they important?

A: The basket is fabricated from either SS 304 or SS 316 stainless steel, ensuring excellent durability and chemical resistance. This makes the centrifuge suitable for handling a wide range of corrosive materials typically found in chemical, pharmaceutical, and food processing industries.Q: When should I select top or bottom discharge for my application?

A: Top discharge is preferred for easy manual unloading and batch processes, while bottom discharge is suitable for automated continuous workflows or when handling wet cake discharges. The choice depends on your material type, batch size, and desired level of automation.Q: Where is this centrifuge commonly used?

A: This model is predominantly used in chemical, pharmaceutical, and food processing plants, where efficient separation of solids from liquids is essential. Its robust design is ideal for demanding applications and frequent usage.Q: What is the processing capacity and operational speed of this centrifuge?

A: The machine offers a processing capacity between 100 kg/hr and 500 kg/hr and can reach a maximum speed of 2500 rpm, making it suitable for medium to high-volume production environments.Q: How do I maintain the 4 Point Suspension Centrifuge?

A: Routine cleaning of the basket and external surfaces, periodic inspection of drive components and suspension points, and adhering to manufacturer-recommended maintenance schedules will ensure optimal performance and longevity of the centrifuge.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centrifuge Hydro Extractor Category

Beg Lifting 4 Point Suspension Centrifuge

Price 325000 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50 Hz

Dimension (L*W*H) : Customizable

Weight : 250500 kg

Capacity : 100500 Ltr

Textile Hydro Basket

Price 150000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Frequency (MHz) : 50 Hz

Dimension (L*W*H) : 700 x 700 x 950 mm

Weight : Approx. 6090 Kg

Capacity : 3050 Kg/Batch

Centrifugal Hydro Extractor

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50 Hz

Dimension (L*W*H) : 1100 mm x 720 mm x 980 mm

Weight : 850 kg

Capacity : 60100 kg per batch

SS Centrifuge

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50 Hz

Dimension (L*W*H) : 800 x 600 x 1000 mm (varies with capacity)

Weight : 150650 kg (approx.)

Capacity : 30 to 500 Litres (as per model)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry