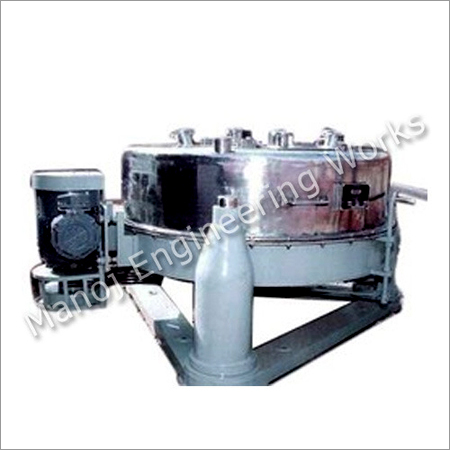

Industrial Centrifuge Machine

Price 150000 INR/ Unit

Industrial Centrifuge Machine Specification

- Type

- Industrial Centrifuge Machine

- Material

- Stainless Steel

- Capacity

- 500-1000 Liters per hour

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Voltage

- 380 V

- Frequency (MHz)

- 50 Hz

- Size

- Standard

- Width

- Customized

- Weight

- Approx. 500 kg

- Dimension (L*W*H)

- 1800 x 1200 x 1500 mm

- Finish

- Polished Surface

- Installation

- Floor Mounted

- Speed Range

- 1200 - 2500 RPM

- Maintenance Interval

- 6 Months

- Drum Type

- Horizontal Basket

- Operating Temperature

- 0°C to 60°C

- Humidity Tolerance

- Up to 95% RH

- Motor Power

- 7.5 kW

- Application

- Chemical, Pharmaceutical, Food Processing, Industrial Separation

- Noise Level

- <75 dB

- Discharge Type

- Bottom Discharge

- Control Panel

- Digital/Analog

- Inlet/Outlet Size

- Standard 2" / 3" ports

- Safety Features

- Overload Protection, Emergency Stop Button

About Industrial Centrifuge Machine

Industrial Centrifuge Machine

An 3 Point Suspension Industrial Centrifuge Machine is designed to separate fluid/particle. This machine uses centrifugal force for solid-liquid separation, liquid-liquid separation, liquid-liquid-solid separation. The law of physics that governs the centrifugal separation is called as Stokes Law. We provide both, filtering and sedimentation industrial centrifuge machines. A number of process industries use the industrial centrifuges, waste water processing, chemical processing, pharmaceutical and biotechnology Industries, fuel and bio fuel industries, food processing, mining and mineral processing, to name a few.

Product Specification

| Condition | New |

| Style | Three Point |

| Voltage | 380V |

Product Description

We are engaged in offering a wide range of Three Point Suspension Centrifuge that is widely appreciated for high operational efficiency and negligible maintenance.

Versatile Industrial Separation

Engineered for versatility, this centrifuge excels in chemical, pharmaceutical, and food processing applications. Its horizontal basket design ensures thorough separation of solids and liquids, optimizing batch yields and reducing process times. Standard inlet and outlet ports allow for seamless integration with existing workflows, supporting both small-scale and large-scale operations.

Reliable Performance & Safety

Every component, from the polished stainless steel housing to the advanced control panel, is built to withstand the rigors of industrial operation. Users benefit from safety features such as overload protection and an emergency stop button, ensuring both personnel and equipment are protected during operation. Maintenance intervals of six months minimize downtime while supporting consistent productivity.

FAQs of Industrial Centrifuge Machine:

Q: How does the industrial centrifuge machine discharge separated material?

A: The centrifuge uses a bottom discharge system, allowing processed materials to exit efficiently from the lower section of the horizontal basket. This promotes quick removal and optimizes batch handling for various industrial processes.Q: What are the primary applications for this centrifuge machine?

A: This machine is designed for separation processes in chemical, pharmaceutical, and food processing industries. It effectively separates liquids and solids, making it ideal for product purification and clarification requirements.Q: When should scheduled maintenance be performed on the centrifuge?

A: Scheduled maintenance is recommended every six months to ensure optimal performance and longevity. Regular maintenance includes checking mechanical components, inspecting safety features, and ensuring the drum remains clean and balanced.Q: Where is this centrifuge machine typically installed?

A: The unit is floor-mounted and suitable for versatile industrial environments. Its robust design allows installation in processing facilities, laboratories, and manufacturing plants requiring high-capacity separation solutions.Q: What safety features are included to protect operators and equipment?

A: Key safety features include overload protection and an emergency stop button on the control panel. These mechanisms safeguard against unexpected operational issues, promoting a safe working environment.Q: How does the control panel aid in operating the centrifuge machine?

A: Operators can choose between digital or analog controls to monitor and adjust speed, temperature, and other operating parameters. This ensures precise separation and enhances ease of use for varying process requirements.Q: What are the benefits of using a polished stainless steel finish and robust material construction?

A: The polished stainless steel construction guarantees durability, corrosion resistance, and hygiene, particularly important in chemical and food processing applications. It also simplifies cleaning and contributes to the machines long-term reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centrifuge Hydro Extractor Category

Beg Lifting 4 Point Suspension Centrifuge

Price 325000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : 4 Point Suspension Centrifuge

Frequency (MHz) : 50 Hz

Material : Stainless Steel

Voltage : 220440 V

4 Point Suspension Centrifuge

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : 4 Point Suspension Centrifuge

Frequency (MHz) : 50 Hz

Material : Stainless Steel

Voltage : 380 V

Textile Hydro Basket

Price 150000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Type : Hydro Basket

Frequency (MHz) : 50 Hz

Material : Stainless Steel

Voltage : 220 V

SS Centrifuge

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Centrifuge Machine

Frequency (MHz) : 50 Hz

Material : Stainless Steel (SS)

Voltage : 220415 V

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry