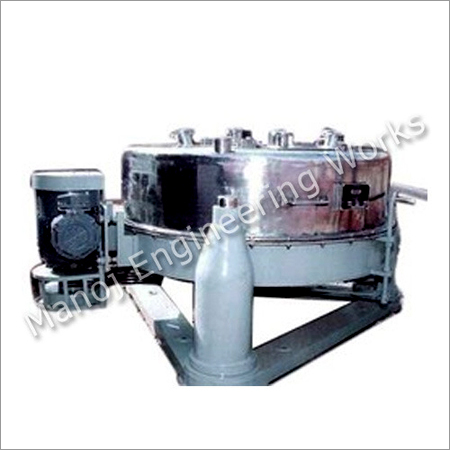

Centrifugal Hydro Extractor

Price 150000 INR/ Unit

Centrifugal Hydro Extractor Specification

- Type

- Centrifugal Hydro Extractor

- Material

- Stainless Steel

- Capacity

- 60-100 kg per batch

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Voltage

- 415 V

- Frequency (MHz)

- 50 Hz

- Size

- Standard Industrial

- Width

- 720 mm

- Weight

- 850 kg

- Dimension (L*W*H)

- 1100 mm x 720 mm x 980 mm

- Application

- Textile, Laundry, Chemical, Pharmaceutical Industries

- Noise Level

- Low

- Discharge Type

- Bottom Discharge

- Max Speed

- 1200 RPM

- Safety Features

- Automatic Balancing, Door Safety Interlock

- Control Panel

- Manual Rotary Switch

- Finish

- Polished

- Drive Motor Power

- 5 HP

- Power Supply

- Three Phase

- Frame Construction

- Rugged Mild Steel with Epoxy Coating

- Moisture Removal Efficiency

- Up to 97%

- Basket Material

- Heavy-Duty Stainless Steel

- Installation

- Floor Mounted

Centrifugal Hydro Extractor Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- vadodara

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

About Centrifugal Hydro Extractor

We are manufacturer and exporter of a precision engineered range of Centrifugal Hydro Extractor that is specially designed for application in diverse industry processes. These are available in desired technical specifications and are known for reliable performance. Available to clients as per their requirement, we offer these at industry leading prices without any compromise of functionality.

Technical Specification

- Suspension: Having 3 Nos. of heavy duty, sturdy, C.I. Legs with spring steel springs to prevent vibration

- Brake: Specially designed very efficient hand/show brake, mechanically designed which can stop the basket in 5-10 min

- Base Frame: Entire centrifuge fitted on M.S. channel base frame and comes to you in assemble condition.

- Rubber Lining: Centrifuge.

Product Specification

| Condition | New |

| Motor Power | 3 HP |

| Automatic Grade | Automatic |

Product Description

We are a leading manufacturer and supplier ofCentrifugal Hydro Extractorto our valuable clients.

Precision Moisture Extraction

Delivering superior moisture removal efficiency up to 97%, this centrifugal hydro extractor optimizes the drying process. Its rapid spinning action and heavy-duty stainless steel basket ensure thorough extraction, minimizing fabric retention times and promoting faster downstream processing.

Built for Industrial Durability

Constructed with a rugged mild steel frame, protected by an epoxy coating, and a polished stainless steel basket, the extractor withstands continuous industrial use. Floor mounting provides stability, while the low-noise design ensures a comfortable working environment.

Safety and Simple Operation

Automatic balancing and door safety interlock systems safeguard operators, while the manual rotary switch allows for intuitive semi-automatic control. The bottom discharge mechanism enhances usability, supporting efficient batch processing in various industrial settings.

FAQs of Centrifugal Hydro Extractor:

Q: How is the Centrifugal Hydro Extractor operated in an industrial setting?

A: The extractor functions using a semi-automatic control system managed by a manual rotary switch, allowing operators to initiate and stop cycles and control speed settings easily. Its floor-mounted installation ensures stability during high-speed operation.Q: What safety features are included to protect users during operation?

A: Safety is prioritized with automatic balancing to prevent uneven loads and a door safety interlock that keeps the machine from operating if the door is improperly closed, minimizing the risk of accidents.Q: Where can this extractor be used, and what materials is it suited for?

A: This model is suitable for textile, laundry, chemical, and pharmaceutical applications. Its heavy-duty stainless steel basket can handle various materials, including fabrics, chemicals, and powders requiring effective moisture extraction.Q: What process does the machine use to remove moisture from materials?

A: It employs centrifugal force by spinning at up to 1200 RPM, separating moisture from materials loaded into the basket. The extracted liquid exits through the bottom discharge, maximizing drying efficiency and throughput.Q: When should maintenance or inspection be performed to ensure optimal operation?

A: Routine checks on the drive motor, safety interlocks, and basket condition should be performed periodically in accordance with the manufacturers guidelines, typically before and after each batch run for industrial reliability.Q: What are the notable benefits of choosing this hydro extractor for industrial use?

A: Users benefit from high moisture removal efficiency, robust construction for long-term durability, low noise levels, both operational and safety features, and the ability to handle large batch capacities, thus improving workflow and productivity.Q: How does the bottom discharge mechanism improve batch processing efficiency?

A: The bottom discharge enables quick, easy removal of processed materials without manual intervention, streamlining transitions between batches and reducing downtime for industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centrifuge Hydro Extractor Category

Beg Lifting 4 Point Suspension Centrifuge

Price 325000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : 250500 kg

Voltage : 220440 V

Frequency (MHz) : 50 Hz

Material : Stainless Steel

4 Point Suspension Centrifuge

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : 450 kg (Approx)

Voltage : 380 V

Frequency (MHz) : 50 Hz

Material : Stainless Steel

Textile Hydro Basket

Price 150000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Weight : Approx. 6090 Kg

Voltage : 220 V

Frequency (MHz) : 50 Hz

Material : Stainless Steel

SS Centrifuge

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : 150650 kg (approx.)

Voltage : 220415 V

Frequency (MHz) : 50 Hz

Material : Stainless Steel (SS)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry