Call: 07971189569

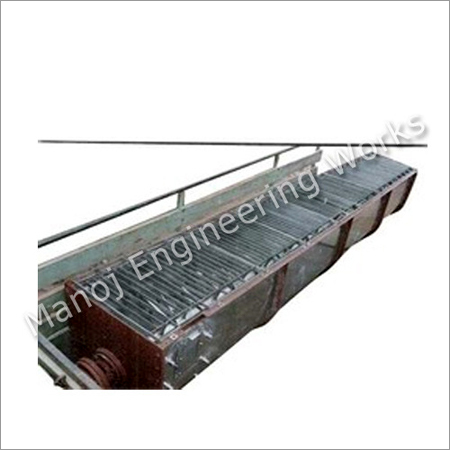

Industrial Ribbon Blender

Price 155000 INR/ Unit

MOQ : 1 Unit

Industrial Ribbon Blender Specification

- Blade Type

- Ribbon Blades

- Features

- Efficient mixing durable design

- Frequency

- 50 Hz

- Voltage

- 220-240 V

- Orientation

- Horizontal

- Drive Type

- Electric Motor

- Application

- Mixing powdered and granular materials

- Mounting Type

- Floor-mounted

- Noise Level

- Low

- Mixing Speed

- 15 RPM

- Surface Finish

- Polished

- Motor Power

- 5 HP

- Type

- Industrial Ribbon Blender

- Material

- Stainless Steel

- Capacity

- 500kg/batch

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Cooling System

- None

- Power(W)

- 3.75 kW

- Shape of Tank

- Cylindrical

- Loading Capacity

- 500 kg

- Mixer Type

- Ribbon Mixer

- Size

- Large

- Width

- 800 mm

- Dimension (L*W*H)

- 2000x800x1000 mm

- Weight (kg)

- 750 kg

- Color

- Silver

- Warranty

- 12 Months

About Industrial Ribbon Blender

Industrial Ribbon Blender

Features:

- High Performance

- Compact design

- Corrosion resistant

- Robust structure

Product Specification

| Design Type | Customized |

| Capacity | 700 L |

| Condition | New |

Product Description

We are engaged in manufacturing and supplying of Ribbon Blender to our valuable clients.

Efficient and Uniform Mixing

The ribbon blenders unique blade design ensures thorough mixing of ingredients, achieving a homogenous blend in each batch. This makes it ideal for applications involving powders and granules where consistency is critical. The large 500 kg capacity caters to medium-to-large scale production needs.

Rugged Stainless Steel Construction

Constructed entirely from stainless steel, this blender offers corrosion resistance, longevity, and minimal maintenance. The polished surface finish not only provides a sleek appearance but also aids in easy cleaning and hygiene compliance in industrial settings.

Easy Operation and Safety

The semi-automatic system and accessible control panel simplify the mixing process, reducing manual effort and operational hazards. Floor-mounted with a stable base, the design ensures both safety and ease of installation.

FAQs of Industrial Ribbon Blender:

Q: How does the Industrial Ribbon Blender operate?

A: This ribbon blender uses a 5 HP electric motor to rotate ribbon blades within a cylindrical tank, mixing powdered and granular materials thoroughly. The operator manages the semi-automatic controls to load, blend, and discharge batches efficiently.Q: What types of materials can be blended with this machine?

A: It is designed for mixing powdered and granular substances, making it suitable for food, chemical, pharmaceutical, and construction materials where consistent texture and blend quality are essential.Q: When should I choose a semi-automatic ribbon blender over a fully automatic option?

A: A semi-automatic blender is ideal when you need some manual operation for flexibility, lower upfront cost, and simpler maintenance. Its especially suited for medium-scale production environments where full automation isnt required.Q: Where is this mixer typically installed?

A: This floor-mounted ribbon blender is usually installed in industrial processing plants such as food manufacturing units, chemical factories, or construction material facilities, where stable and secure setup is important.Q: What is the process for using the ribbon blender?

A: The operator loads materials into the tank, sets the control panel, and starts the blending cycle. The ribbon blades rotate at 15 RPM, mixing the batch uniformly. Once the process completes, the blended product is discharged for further packaging or processing.Q: What are the key benefits of using this industrial ribbon blender?

A: Benefits include efficient and uniform mixing, durable stainless steel construction, low noise operation, and ease of cleaning. Its large capacity and efficient design boost productivity and reliability in industrial environments.Q: Is maintenance required often for this equipment?

A: Routine maintenance is minimal, thanks to the durable design and stainless steel material. Regular inspections and cleaning after each batch are recommended for optimal performance and longevity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry