Call: 07971189569

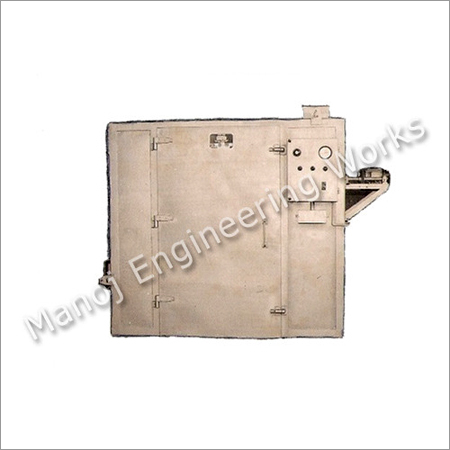

Electric Tray Dryer

Price 150000 INR/ Unit

MOQ : 1 Unit

Electric Tray Dryer Specification

- Accuracy

- 1C

- Heating Method

- Electrically Heated

- Condition

- New

- Power Source

- Electric

- Control Mode

- Digital Temperature Controller

- Heating Capacity

- 3 KW

- Type

- Tray Dryer

- Model

- Electric Tray Dryer ETD-24

- Internal Size

- 950 mm x 450 mm x 900 mm

- External Size

- 1150 mm x 600 mm x 1200 mm

- Volume

- Approx. 380 Liters

- Air Flow

- Forced Air Circulation

- Temperature Range

- Ambient to 250C

- Material

- Stainless Steel

- Dimension (L*W*H)

- 1150 mm x 600 mm x 1200 mm

- Power

- 3 kW

- Voltage

- 220V / 50 Hz

- Surface Finish

- Polished

- Weight

- Approx. 320 kg

- Insulation

- Glass Wool

- Noise Level

- Less than 60 dB

- Tray Material

- Stainless Steel 304

- Door Type

- Double Walled with Gasket

- Blower Motor

- 0.25 HP

- Display

- LED Digital Display

- Safety Features

- Over-temperature Protection

- Application

- Pharmaceutical, Chemical, Food Industries

- Number of Trays

- 24

- Mobility

- Castor Mounted

- Timer

- Programmable 0-999 min

- Tray Size

- 16" x 32" x 1.25"

Electric Tray Dryer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash on Delivery (COD)

- Main Domestic Market

- All India

About Electric Tray Dryer

We hold the industry expertise as manufacturer and exporter of premium quality Electric Tray Dryer that is widely used in many industries for drying various materials. The range of equipment is constructed using premium quality components and sophisticated technology. This machine is designed with high precision in order to meet the international quality and manufacturing standards. Further, we offer these to buyers as per their requirements within a stipulated time frame.

Features:

- Light weight

- Corrosion resistance

- Durability

- Reliability

Product Specification

| Automatic Grade | Automatic |

| Body Material | Stainless Steel |

| Power(W) | 0.25 kW |

Product Description

We hold the proficiency in offering premium quality Electric Tray Dryer that is widely used in many industries for drying various materials efficiently.

Efficient Drying Technology

The ETD-24 utilizes electrically-heated forced air circulation, ensuring even and consistent drying across all 24 trays. Its programmable timer and digital temperature controller offer precise control over drying cycles, providing flexibility for different products and requirements.

Robust, User-Friendly Design

Designed for durability and convenience, the dryer features a stainless steel build, glass wool insulation for heat retention, and double-walled gasketed doors for safety. Castor mounting enhances mobility, allowing easy positioning within laboratories or production facilities.

Safety and Performance Assurance

Integrated over-temperature protection and LED digital display promote operational safety, while a noise level below 60 dB maintains a comfortable working environment. The equipments reliable control system guarantees consistent results with every batch.

FAQs of Electric Tray Dryer:

Q: How does the Electric Tray Dryer ETD-24 ensure uniform drying of materials?

A: The ETD-24 employs forced air circulation through a 0.25 HP blower motor, circulating heated air evenly across all 24 trays. This ensures that each tray receives consistent heat, leading to uniform drying results for pharmaceutical, chemical, or food products.Q: What are the primary benefits of using stainless steel 304 trays?

A: Stainless steel 304 trays provide excellent corrosion resistance, durability, and easy cleaning. These properties support sanitary standards required in pharmaceutical, chemical, and food processing industries, helping prevent contamination and ensuring product quality.Q: When should I use the programmable timer and digital controller features?

A: Use the programmable timer (0999 min) and digital controller for batch drying processes that require precise timing and temperature control. These features are essential when handling sensitive materials or recipes that demand accurate cycle management for optimal results.Q: Where is this tray dryer typically used?

A: The Electric Tray Dryer ETD-24 is widely used in laboratories and production facilities within pharmaceutical, chemical, and food industries. Its design and specifications make it suitable for drying bulk samples, ingredients, and various industrial products.Q: What safety features are included in the ETD-24 model?

A: The ETD-24 provides over-temperature protection to prevent heat-related hazards and is fitted with a double-walled door and gasket for secure sealing. The user-friendly LED digital display also allows monitoring of temperature and drying cycles to enhance operational safety.Q: Can the Electric Tray Dryer be easily moved?

A: Yes, the ETD-24 is equipped with castor wheels for mobility, allowing users to reposition the dryer conveniently within a workspace, laboratory, or production area as needed.Q: What improvements does glass wool insulation bring to the drying process?

A: Glass wool insulation minimizes heat loss during operation, ensuring efficient energy usage and stable internal temperatures. This contributes to faster drying cycles, lower operating costs, and improved safety in the working environment.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry